Digital Transformation of Alel Agro Could Revolutionize the Poultry Industry

In recent years, so much has been said about business digitalization that enterprise leaders often take this phenomenon for granted, without delving into the complexities of such a challenging technological transition. However, business owners must understand that an automated work environment is not a cure-all, but rather a helpful assistant—its efficiency heavily depends on the realism of your plans and goals.

Every company must adopt digitalization only with clear, measurable objectives. Only by aligning the system with your own interests will you achieve impressive performance.

The Three Enemies of Digitalization

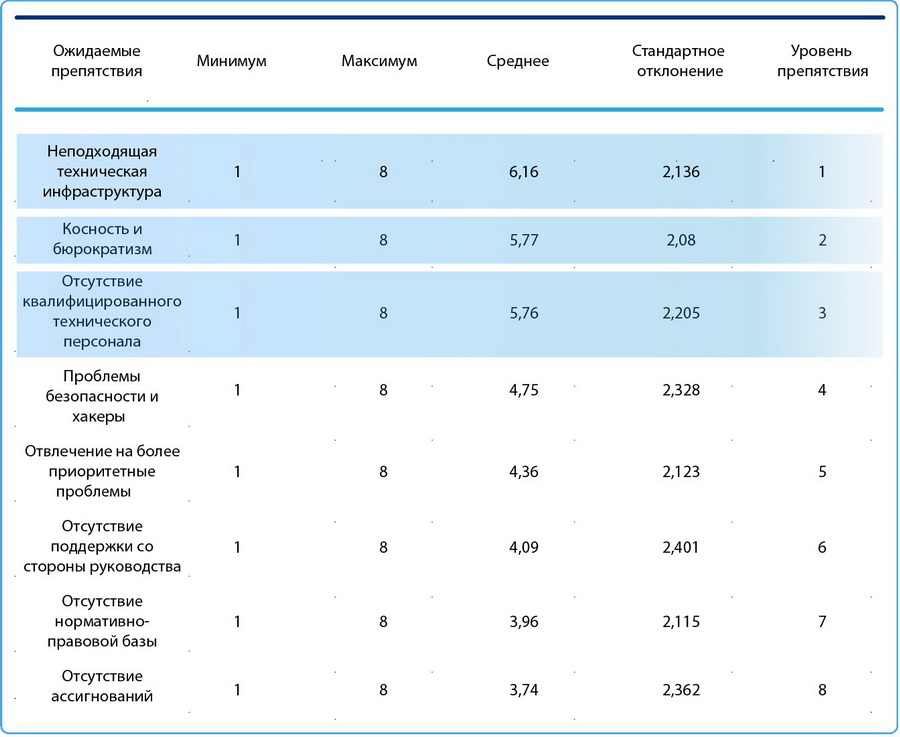

According to a Turkish survey on digitalization expectations among business leaders, the top three barriers to successful digital transformation are:

1. Inadequate technical infrastructure;

2. Inability to abandon old bureaucratic habits;

3. Difficulty hiring qualified personnel.

Interestingly, cybersecurity only ranks fourth. This matches my own observations: many business leaders misunderstand automation as simply swapping an old system for a new one—like updating smartphone apps to boost performance.

Source: www.academia.edu

Interestingly, cybersecurity only ranks fourth. This matches my own observations: many business leaders misunderstand automation as simply swapping an old system for a new one—like updating smartphone apps to boost performance.

Such a mechanical approach, especially in agriculture, simply doesn’t work. I believe that a company’s productivity, regardless of size, depends primarily on its people and how well they adopt the company’s technology and work culture.

Experience of Industry Leaders

In this context, I would like to share an example from my own practice. In July 2023, my team successfully launched a new, fully digital management system into industrial operation for the Kazakhstani company “Alel Agro”. For the client, this means real-time control over almost all components of the business: from poultry meat production at factories to logistics and sales.

As a leader in Kazakhstan’s poultry industry, “Alel Agro” will undoubtedly influence other market players, many of whom have long considered full business process automation. I have no doubt that “Alel Agro” has initiated nothing less than a full-scale digital transition in Kazakhstan’s agro-industry, which will ultimately result in a new business model in this highly complex sector of the economy.

Poultry farm in Ili district, Almaty region. Photo from Alel Agro archives

But if you studied Alel Agro’s market indicators from previous years, you wouldn’t find any serious problems. The company felt confident even before the digitalization era: the team handled standard poultry farming processes, and typical software was used. Why change anything if things were already going well?

The answer lies in the client’s rethinking of value priorities, where the goal is not just another software update, but the creation of a unified, developed ecosystem integrating all geographically dispersed assets. The success criterion for this complex mission should be freeing up the company's time and energy from routine tasks for full-scale, creative enterprise development.

Feed mill. Photo from Alel Agro archives

As the most appropriate solution for this task, one of the well-established ERP systems (enterprise resource planning) was chosen. We all know how chickens grow and what it takes, but how do you find the optimal production mode that gives maximum output with minimum cost?

By managing processes manually, you won’t be able to answer that question. To get a complete picture of production and make timely management decisions, sooner or later you’ll have to consider a new technological structure, which includes a modern ERP system.

Time has shown that the decision made by Alel Agro’s management was strategically correct. It likely stemmed from a deep internal demand for change and a perception of new technologies not as a trend, but as critically important innovation.

What Factors Indicate the Need for Automation

Throughout their lifecycle, agricultural companies gradually accumulate various accounting systems and additional software. Often, document flow, finance, and logistics services poorly interact, which quickly affects work with product catalogues, counterparties, and customers.

Incubator. Photo from Alel Agro archives

How does this internal chaos emerge? Initially, the company reasonably chooses the simplest solution for its basic needs. As the business grows, new modules and apps are added, supported and customized through in-house development.

At first glance, a couple of in-house programmers seem cheaper than an outsourced team, but such savings inevitably make the company dependent on the qualifications and capacity of its internal IT resources. Worse still, instead of a well-designed ecosystem, the client ends up with a patchwork of programs and subsystems requiring separate maintenance and updates.

As a result, outdated platforms and isolated information affect business manageability, increasing operational costs and decreasing labor productivity. Entire islands of automation emerge, surrounded by local information spaces with no integration capability and no unified computing core.

Poultry farm. Photo from Alel Agro archives

Managing such an enterprise resembles a boxer’s clinch: any serious analytics takes weeks or months, and real-time management decisions are out of the question. Management doesn’t always see the situation as critical, since problems are partially solved by constantly patching holes and fixing failures locally.

And in this half-fainting state, a company can exist for years, even decades, always at risk of collapsing into a full-blown crisis. A routine event could trigger collapse: the resignation of a multi-skilled programmer, retirement of old-school tech experts, or simple sabotage on certain job sites.

If your company is at this stage of technological disintegration, now is the time to consider implementing a holistic concept of a digital ecosystem.

How to Estimate the Budget for ERP Implementation

There is no single universal formula, since each company has its own specific needs. From my experience, the annual automation budget is 1–2% of company turnover. If we simplify the budget estimation, I’d suggest using the average cost of automating a single workplace.

Feed mill. Photo from Alel Agro archives

Of course, the cost of automating a warehouse worker’s station will differ greatly from that of a finance department employee. That’s why average estimates are used. For example, the cost per workplace might range from $1,000 to $4,000. The average estimate is about $2,000–2,500. More accurate figures can be provided only after a pre-project survey of the client’s enterprise.

It’s also important to note that the number of unique (client-specific) requirements significantly affects the project cost. Conversely, using a system “as is” significantly reduces digitalization costs, not to mention saved time and stress. The key is to choose integrators experienced in the industry relevant to the client.

Of course, this article format does not allow a more detailed explanation of the digitalization preparation stage, but I hope to share more about this in future materials.

Andrey Ivanchikov

Author Information:

Andrey Ivanchikov, co-owner and COO of "RASK. IN-AGRO". The company is a recognized leader in digitalizing the agricultural sector in Ukraine. More than 5,000 Ukrainian enterprises use “RASK. IN-AGRO” automation products in accounting, including top agribusinesses: “Astarta,” “Ukrlandfarming” (“Avangard”), “Agroprosperis,” “Continental Farmers Group (Salic),” “Kernel,” and many others. Ukrainian developers debuted in the Kazakhstani market in 2010 when the company was invited to cooperate by the agro-industrial enterprise “Ivolga Holding.” Among RASK. IN-AGRO clients are major Kazakhstani companies and holdings: BI Group, ISKER, JSC Aitas Kz, “Alel Agro.”